Cycle Isolation: Monitoring for Better Usage

By Greg C. Alder | Published in Valve Magazine

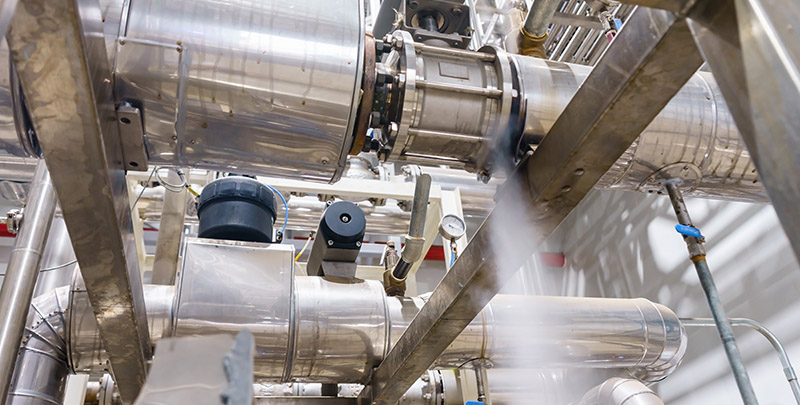

One of the largest controllable losses in power plants is leakage-based energy loss. These losses, which have been documented at more than 400 British Thermal Units per kilowatt hours (Btu/kWh) in some cases, are often overlooked because of the difficulty in spotting them in systems that have hundreds of potentially leaking valves.

For plants using combined cycles, the losses can be even greater since the overall cycle efficiency is based on excess energy used via a steam turbine cycle to generate electricity—energy that can be lost through leaks. The energy losses from these undetected leaks also damage the affected valves continuously, which increases the leakage and the losses in generation, and often the overall heat rate in the valve system. All those factors potentially lead to early failure or even forced outage for maintenance and replacement.

CYCLE ISOLATION AND ITS BENEFITS

Cycle isolation is the process of recapturing lost power by monitoring valve system flows for potential leakages through downstream temperature information. It is used in all types of power plants.

These temperatures can be collected manually from plant walk-downs or from real time data when available. The data collected is then used to generate leakage data and alerts. By monitoring the flows within a cycle (called internal isolation) and accounting for all flows entering and leaving a cycle (called external isolation), cycle isolation technology assures that all steam and water flows are going to their proper destinations, maximizing efficiency and minimizing energy losses from leaks.

By understanding and evaluating a valve system’s performance data, users can balance energy production losses against unplanned outages. They also can determine the maintenance schedule most advantageous for a particular plant.

Cycle isolation is the process of recapturing lost power by monitoring valve system flows for potential leakages through downstream temperature information.

Establishing or modernizing a cycle isolation valve monitoring program reduces the time between when a leak begins and when it is found and resolved, which helps to eliminate major losses to plant efficiency. This potentially results in decreased heat rate, increased power generation, decreased fuel usage, decreased water production costs, elimination of potential valve damage and decreased maintenance costs.

Cycle isolation studies indicate a typical savings in a power plant of 1 megawatt (MW) per unit (which saves about $250,000 per year at $29 per MW an hour) and a 1.3% power generation increase as a result of cycle isolation improvements, proving both the devastating potential losses from leaks and the overall effectiveness of cycle isolation.

WHY VALVES LEAK

Aging plants, deteriorating valve performance and increased demand for electric power are all potential causes of efficiency and power generation losses in plant systems. Beyond these general circumstances are several more specific reasons for valve leakages, including high temperatures and differential pressure, severe service, and cycling of the valves open and closed, especially in cycling units. But these aren’t the only reasons leaks occur; leakage also can result from maintenance on a system, foreign material in the valve, tank level control problems, air-operated valve setting issues, motor-operated valve thermal expansion, relief valve drifting, steam cutting of valves and improper valve alignment. All of these factors have documented impacts on the health of a system and its total leakage.

Aging plants, deteriorating valve performance and increased demand for electric power are all potential causes of efficiency and power generation losses in plant systems.

Though leakage can occur anywhere in a system, common loss areas highlighted by cycle isolation are places such as start-up drains, feedwater heater vents and drains, turbine bypass systems, soot-blower thermal drains, relief valves, pegging steam valves, feed pump recirculation valves, steam seal systems, steam drain line orifices and steam traps. High-energy valve leakages in areas like these don’t only reduce plant efficiency and power generation, they also can lead to increased heat rates, potential valve damage, increased fuel usage, increased water production costs and increased maintenance costs.

HOW CYCLE ISOLATION WORKS

Cycle isolation works by gathering, monitoring and then calculating a system’s flow and its changes to identify leaks and power losses in a plant’s systems. First, site personnel identify a list of potential areas and valves at high risk for leakage through plant piping and instrumentation diagrams, isometrics, heat balance diagrams, and plant walk-downs. Though all valves in a system may not be capable of being monitored, establishing a list of high energy or frequently repaired valves will give a picture of the most optimal placements for cycle isolation monitoring. Also, ranking valves and prioritizing potentially leaking valves makes the process of cycle isolation more efficient. For example, large and vital valves are expensive to repair, so to maximize efficiency, their needs should be considered first. Consulting with plant operators and maintenance personnel helps to identify areas of frequent issue or repair, which identifies areas that will be ideal for monitoring.

Once this information is compiled, an ideal walk-down order for the most efficient data collection is determined, and a frequency for walk-down measurements to monitor valve changes over time is decided. Many plants even place numbers at the measurement locations to correspond with walk-down collection forms.

Plant operators often are involved with developing cycle isolation walk-downs and walk-down procedures, which benefits the process by increasing those operators’ awareness of the importance of monitoring potentially leaking valves and efficiency losses for their plants. These walk-downs and procedures are designed to reinforce understanding of the measurement equipment and the locations monitored by cycle isolation for those performing the measurements.

Cycle isolation works by gathering, monitoring and then calculating a system’s flow and its changes to identify leaks and power losses in a plant’s systems.

Measurement monitoring equipment locations are then set up in the most ideal locations in the valve system. A variety of sensors, including infrared, contact pyrometer, thermocouple and resistance temperature detector (RTD) measurement devices, have all been used in fossil fuel, combined cycle and pressurized water reactor nuclear plants. Though the options are more limited because of radioactive environments, even boiling water-reactor nuclear plants can use cycle isolation monitoring through thermocouples or RTD devices to collect cycle isolation data.

In some cases, thermography readings can be used. Because temperature data can be affected by many factors—including other plant equipment, pipe diameter changes, headers, measuring too close to a condenser and other issues, such as plant geometry that doesn’t allow measuring at optimum locations—the most important factor is consistency of the measurement locations.

After an isolation list, walk-down order and measurement equipment are established, plant personnel can begin to use the data collected for optimizing isolation losses. The temperature data, which is either manually or digitally recorded, includes dates, valve information and valve temperatures. It is used to monitor changes. This data also allows for better scheduling of maintenance; however, because repairs can often cause a change in the system, it is critical to maintain documentation of each valve repair. After a valve is repaired, cycle isolation should be used to measure the temperatures to make sure the valve is fully repaired, then monitoring is continued to make sure the leakage does not return.

Based on the user’s preferred calculation methods, this data is then used to calculate the leakage flow and losses by inferring pressure inside pipes from downstream temperature measurement. To do so, valve upstream thermodynamic properties, piping configuration and sink conditions are used to calculate flow, the value of leaking fluid (high-energy, high-value) and then flow-to-heat rate is converted, or generation loss and cost is figured. These calculations are vital for maintenance scheduling, especially in predictive maintenance. Beyond indicating what systems currently require maintenance, the calculations can show if a system can continue operating until the next scheduled outage or if immediate action should be taken for a potential leak.

CONCLUSION

Leakage reduces plant efficiency and power generation on a regular basis; however, cycle isolation technology can identify and gauge leaks and their level of severity to prevent and remedy the damage as well as energy loss from the leakage. Because valves can be expensive to repair or replace, estimating the impact leakage has on the cycle’s performance helps to justify maintenance of valves; provides estimations for heat rate and generation improvements, and provides justification for valve repair and replacement. By establishing a simple process of data collection and calculation, cycle isolation can help users diagnose current issues, plan future outages and maintenance, and get a better grasp on the overall health of a system, which saves time, money and many megawatts.

Greg C. Alder is the plant optimization manager for Curtiss-Wright’s Nuclear Division (www.cw-connect.com). He is also a Technical Fellow for Curtiss-Wright Corporation. Reach Greg at galder@curtisswright.com.