Case Study

|

09/06/23

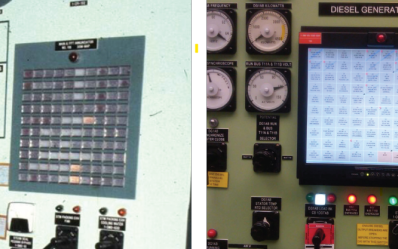

Nuclear Control Room Annunciator System Upgrades Case Study | D.C. Cook

Nuclear power plants rely on annunciators to provide immediate visual and audio indications of plant systems and equipment. When American Electric Power needed to upgrade the annunciator systems at its Donald C. Cook Nuclear Plant, it retained Curtiss-Wright to replace these systems in both nuclear units.

Case Study

|

01/30/23

Mobile Check In App Case Study | DTE Energy

Employing about 850 workers and supplying 20 percent of the power generated by DTE Energy, the Fermi 2 Power Plant is an important part of DTE’s balanced energy portfolio.

News

|

07/27/22

Curtiss-Wright Wins Two Supplier of the Year Awards from the Utilities Service Alliance for the Second Consecutive Year

Curtiss-Wright announced today that it received two Supplier of the Year awards from the Utilities Service Alliance in the Materials and Technology award categories. This achievement marks the second consecutive year Curtiss-Wright received awards in both categories.

News

|

06/30/22

Curtiss-Wright Receives Entergy Premier Vendor Award for Implementation of Condition Monitoring Software Across Entergy’s Nuclear Power Fleet

Curtiss-Wright announced today that it has received the Entergy Premier Vendor Award for Continuous Improvement in recognition of its successful implementation of condition monitoring software across Entergy Corporation’s nuclear power fleet.

News

|

02/10/22

Curtiss-Wright and Teledyne FLIR Defense Sign Agreement to Provide Unmanned Systems and Integrated Solutions to the U.S. Nuclear Power Market and Department of Energy

Curtiss-Wright Corporation announced today that it has entered into an agreement with Teledyne FLIR Defense to supply unmanned systems and integrated solutions to the U.S. nuclear power market and Department of Energy (DOE).

Case Study

|

10/15/21

Curtiss-Wright Expedites Digital Upgrade Project During COVID Shutdown

When a large Midwestern utility decided to retire its legacy PPC system in favor of a modern digital alternative, project stakeholders at the plant turned to Curtiss-Wright for guidance. Due to rigorous COVID-19 safety protocols, completing the project required an extra measure of planning, project management, and ingenuity.

Event

|

08/12/21

2021 Virtual UFSAR Workshop

8/12/2021-8/13/2021

Virtual

Event

|

08/02/21

2021 Significant Determination Process (SDP) Virtual Seminar

8/2/2021-8/3/2021

Virtual

News

|

07/01/21

Curtiss-Wright Wins Two Supplier Of The Year Awards From The Utilities Service Alliance For Nuclear Industry Technology And Materials

Curtiss-Wright’s Nuclear Division announced today that it received two Supplier of the Year awards from the Utilities Service Alliance (USA) in the Materials and Technology award categories.

News

|

06/24/21

Curtiss-Wright Selected to Participate in the Development of Digital Twin Technology for Advanced Nuclear Reactors

Curtiss-Wright Corporation (NYSE: CW) today announced that it has been selected to participate in Project SAFARI, a U.S. Department of Energy-funded project to develop Digital Twin technology for advanced nuclear reactors.

Case Study

|

06/14/21

Digital Safety System Case Study | South-Ukraine

South-Ukraine Nuclear Power Plant has had no failures and no reactor shutdowns due to system errors after replacing their aging safety systems with new EFAS and RTS systems based on the RadICS digital safety platform. Learn more.

Article

|

06/04/21

Nuclear I&C Modernization: The Future is Digital

In this Nuclear News article, Robert Ammon explains why the modernization of safety instrumentation and control (I&C) systems holds significant potential to transform plant operations.