Curtiss-Wright Connect

Curtiss-Wright offers a broad portfolio of digital solutions for the global power and process markets.

Curtiss-Wright's suite of plant performance products is built on 30+ years experience supporting the power industry. Using the latest digital technologies, we develop specialized solutions that optimize fossil plant performance and operations.

Curtiss-Wright's predictive maintenance, equipment condition monitoring, and valve leak management applications allow production, operations, and maintenance personnel to make informed, proactive decisions on all aspects of process and system management. We offer both on-site and cloud-based solutions for use in steel, chemical, and other industrial applications.

Equipment condition monitoring and predictive maintenance play integral roles in the process industries. Curtiss-Wright's solutions offer real-time asset performance management - allowing for early detection and resolution of issues for petrochemical plants, pulp and paper mills, and other processing facilities.

Curtiss-Wright's predictive maintenance platform, supply chain and inventory applications, and plant performance suite of products increase efficiency and optimize performance for the wind, solar, geothermal, and other renewable power markets.

With over 55 years experience supporting the global nuclear power industry, Curtiss-Wright has developed custom applications and digital solutions compliant with the industry's stringent quality requirements and evolving nuclear standards.

Solutions

Performance & Operations Process Control Systems Regulatory Compliance Supply Chain & Inventory Data Analytics & ITPerformance & Operations

Curtiss-Wright offers an integrated suite of products for monitoring, analyzing, and optimizing plant performance. Our specialized software features real-time data analysis for thermal performance, advanced pattern recognition, fault tree analysis, and asset condition monitoring.

Read moreProcess Control Systems

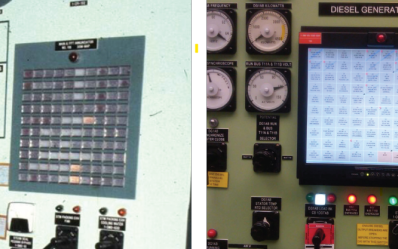

Curtiss-Wright provides specialized process control systems for the nuclear power industry, including the Digital Safety System - a fully qualified, Safety-Related digital I&C platform.

Read moreRegulatory Compliance

Curtiss-Wright's regulatory compliance solutions streamline and automate screening, authorization, and authorization procedures to get workers on-site as efficiently as possible. By eliminate manual processes, our digital applications improve accuracy while reducing processing time, errors, and data loss.

Read moreSupply Chain & Inventory

Curtiss-Wright's suite of supply chain and inventory solutions offer more than a repository of product data and availability. These robust, web-based platforms facilitate sourcing and exchange for spare parts; inform users of obsolescence issues; and enable knowledge sourcing for peer expertise and solutions.

Read moreData Analytics & IT

Curtiss-Wright's portfolio of digital solutions includes specialized data analytics and IT solutions including mobile software development, custom cloud-based solutions, and tailored applications for data analysis and reporting.

Read moreApplications

Improve Thermal Performance Equipment Condition Monitoring Valve Leak Detection Predictive Maintenance Operating Experience ExchangeImprove Thermal Performance

Power plants face a critical challenge in the optimization of thermal performance - identifying and eliminating inefficiencies. Curtiss-Wright offers a suite of thermal performance applications designed for rapid finds and diagnostics, along with testing, modeling, and training services to support your thermal performance programs.

Read moreEquipment Condition Monitoring

Curtiss-Wright's intelligent equipment condition monitoring platform offers real-time asset health analysis and tracks progress towards damage. Using Advanced Analytics technology, our integrated solution allows you to to maintain equipment health, minimize downtime, and increase productivity.

Read moreValve Leak Detection

Aging plants, deteriorating valve performance, and increased demand for electric power require careful monitoring for potential loss of efficiency and generation. Curtiss-Wright's valve leak detection detects cycle isolation issues and automatically estimates the leakage rate as well as generation and heat rate impacts for each leaking valve.

Read morePredictive Maintenance

Curtiss-Wright's advanced pattern recognition solution offers real-time analysis of current and future equipment states to monitor and detect abnormal operating conditions and predict upcoming failures before they happen. Enhance plant productivity and lower the likelihood of asset loss and injury caused by catastrophic failure.

Read moreOperating Experience Exchange

Curtiss-Wright's Operating Experience (OE) Exchange platforms are moderated, real-time, web-based communities dedicated to knowledge transfer among industry peers.

Read more